Een gascentrale die geen CO2 uitstoot?

7 april 2016 – Het Amerikaanse bedrijf NET Power ontwikkelt een gascentrale die geen CO2 uitstoot. Er wordt een klein testcentrale gebouwd om de werking van de techniek te bewijzen. RTL Nieuws berichtte erover.

Uit het bericht van RTL Nieuws

‘(…) Ondernemers achter het bedrijf NET Power hebben een techniek ontwikkeld waardoor de verbranding van fossiele energie niet meer zorgt voor CO2-uitstoot. In Texas wordt een kleine gascentrale (50 MW) gebouwd. De nieuwe centrale moet investeerders ervan gaan overtuigen dat de nieuwe baanbrekende technologie van Net Power ook echt baanbrekend is. In 2017 hopen de ontwikkelaars een veel grote centrale uit de grond te stampen.

In de gascentrale wordt, via een ingewikkeld proces, CO2 feitelijk keer op keer opnieuw gebruikt. In plaats van een turbine op stoom, heeft de centrale een turbine die werkt op CO2. De ontwikkelaars stellen dat deze nieuwe centrale niet alleen schoner, maar ook efficiënter en goedkoper gaat zijn dan reguliere gascentrales. Net Power kijkt ook naar de mogelijkheid om de techniek te gaan gebruiken bij kolencentrales. (…)’

NET Power’s Allam Cycle technology

Uit de website van Netpower

‘(…) The majority of power plants today – including combined cycle gas turbine (CCGT) and supercritical coal plants – rely on thermal power cycles for energy production. These systems operate by combusting ambient air with a fossil fuel (natural gas, coal, or coal “syngas”) to create heat. In traditional coal plants, this takes place in a large boiler, which boils water to create steam. This expansion from water to steam causes a turbine to turn, creating power. In CCGT power plants, natural gas or coal syngas are ignited in a combustor, where they “explode” and drive a turbine. The turbine exhaust is extremely hot, so it is then used to boil water and drive a second set of turbines (hence the name “combined cycle”). In both cases, steam-based working fluids are essential to the process. (…)

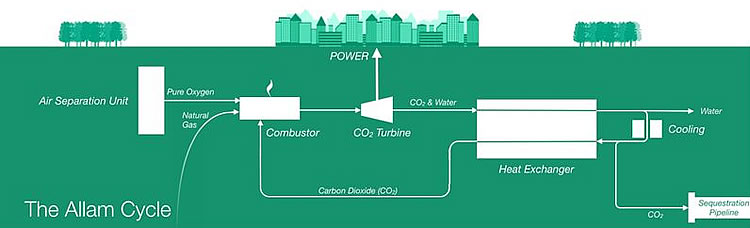

NET Power’s Allam Cycle technology, which uses carbon dioxide as a working fluid to drive a combustion turbine, eliminates all atmospheric emissions without requiring expensive, efficiency-reducing carbon capture equipment, and ultimately produces pipeline-quality CO2 that can be sequestered or used in various industrial processes, including enhanced oil recovery.

“NET Power is the first technology that allows policy and economics to work together, instead of against each other, to ensure the world meets our climate targets,” said NET Power’s CEO, Bill Brown. “Today marks a significant step for our world-class team, including Exelon, CB&I, 8 Rivers and Toshiba, towards delivering a technology that will be the cornerstone of a modern global energy infrastructure that is clean, affordable and flexible.” (…)

NET Power, CB&I, Toshiba, and Exelon have partnered to develop a 50MWth NET Power natural gas demonstration plant. NET Power is responsible for overall project development and systems engineering; Toshiba is developing a new combustor and turbine for the NET Power system, and they successfully tested the combustor in July 2013; CB&I is providing engineering, procurement, and construction services; and Exelon is providing development, permitting, siting, and commissioning services and support. Following successful demonstration at the 50MWth level, the system will be scaled up and the first 500MWth commercial natural gas plant will be built. (…)

‘A high-pressure, highly recuperative, oxyfuel, supercritical CO2 cycle’

Vox over NET Power

‘(…) So what’s the technology? It’s called the Allam Cycle, named after lead inventor Rodney Allam. It is — brace yourself — “a high-pressure, highly recuperative, oxyfuel, supercritical CO2 cycle.”

Let’s see if we can get our heads around that, at least enough to see why it matters. Here’s the diagram:

(…) In typical power plants, fuel is mixed with air and burned. “Oxyfuel” means that Net Power’s plant mixes fuel (in this case, natural gas) with pure oxygen, produced by an air separation unit (ASU). Using pure oxygen rather than air virtually eliminates NOx, one of natural gas’s worst air pollutants. In the combustor, a mix of about 5 percent oxyfuel and 95 percent carbon dioxide is combusted at “supercritical” temperatures and pressure, to drive a turbine. Unlike most electric turbines, which run on steam, the turbine in Net Power’s plant is specially built to run on pressurized carbon dioxide. It is a fluid turbine rather than a steam turbine, with carbon dioxide as the working fluid. (…) After the turbine is spun and the power is generated, the waste fluid (carbon dioxide and water) is put through a heat exchanger, the water condensed out and separated. What’s left is pure (90-plus percent) carbon dioxide, which is then repressurized in a compressor and made ready for pipeline. It can then be used for enhanced oil recovery (EOR) or sequestered. But the bulk of the carbon dioxide is reheated in the heat exchanger and used again in the combustor. That’s what “highly recuperative” means — most of the CO2 is recycled through again and again. So there we are: “a high-pressure, highly recuperative, oxyfuel, supercritical CO2 cycle.” (…)’

Bronnen

RTL Nieuws, 6 april 2016: Amerikaans bedrijf ontwikkelt gascentrale die geen CO2 uitstoot

Website NET Power

Vox Energy & Environment, 5 april 2016: Fossil fuel electricity with no pollution? This company is building a power plant to prove it.

Illustraties: NET Power